iGRAIN Smart App

The iGRAIN Smart App brings you on top of things, it enables you to access your vital grain data while on the move. All available sensory data from your iGRAIN monitoring system e.g. grain temperature, grain moisture, and CO2 are read out in the iGRAIN Smart App for easy access and decision making at any time.

The iGRAIN monitoring system is making an intelligent evaluation of all monitoring data and calculating the risk factor. Data from the monitoring system is sent to the iGRAIN Cloud Server. Here the calculations are made, and the App is executed and updated in real-time.

The App is intended to work with the iGRAIN CO2 Sniffer (CO2 Spoilage Detection). It is the CO2 sensor that makes the calculations and reports conclusive. This means a given silo plant manager can monitor the grain based on the iGRAIN Co2 Sniffer (CO2 spoilage detection). It is the CO2 sensor that makes the calculations and reports conclusive and temperature monitoring. These data will show the grain manager the risk of infestation in all silos.

The iGRAIN Smart App features the following:

- Calculates the infestation

- Showing the stored grain risk factor (0-6)

- Showing the maximum safe storage time

- Showing your inventory

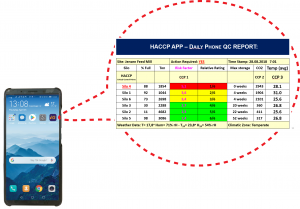

All companies in the food supply chain are under the obligation to conduct food safety control. The use of the principles of Hazard Analysis and Critical Control Point (HACCP) provides a systematic approach of identifying and managing food-safe hazards that may harm the consumers. HACAP does not on its own make the food safe. The iGRAIN® software provides the Critical Control Points (CPP) and makes integration with your host quality control system easy. This makes reporting automatic and decision-making easy.

The App can be downloaded from a link provided for the iGRAIN Dashboard Manager software. The software communicates with the cloud database, from where data is compiled and made available on your smartphone or tablet.

The iGRAIN Smart App is possibly the biggest contribution ever to make the grain managers work easy and validated based on true grain condition.

Advantages:

- Easy access of your grain quality data on the move including Risk Factor Calculation to support your decision making on how to manage your stored crop

- Risk Factor Calculation based upon all available sensory data: grain temperature, grain moisture, and CO2.

- Ranking of your silos according to the quality condition of your stored crop; “worst to best”

- HACCP based

Technical Specifications:

Display of the following information:

- HACCP data for QC reporting etc.

- Risk Factor calculation: 1 – 6

- Ranks all your silos ”Worst to best”. Thereby showing which silos to process next!

- Silo tonnage and percent filling

- Grain temperature

- Grain moisture concentration

- CO2 concentration, indicating spoilage level

- Weather station data

We have a large and exclusive pool of scientific and practical expertise from tailoring and applying post-harvest solutions in any climate zone worldwide, and we shall be honored to serve you.

Please contact our sales and application team at info@i-grain.net for further information and a quote to suit your specific needs; we work together for safe crop for the world!

We recorded the below video at AgriTechnica 2023 – listen to Peer Hansen talking about the Smart App here:

Download PDF