The Subtle Art of Eradicating Mycotoxins in Contaminated Crop

The Food and Agriculture Organization of the United Nations estimates that every year, about 25 percent of food produced globally is destroyed due to Mycotoxin contamination. This has raised the demand for decontamination of crops to which TOXI-SCRUB ApS offers a solution called TOXI-SCRUB Processing Line that increases both food safety and trade revenue amongst its users.

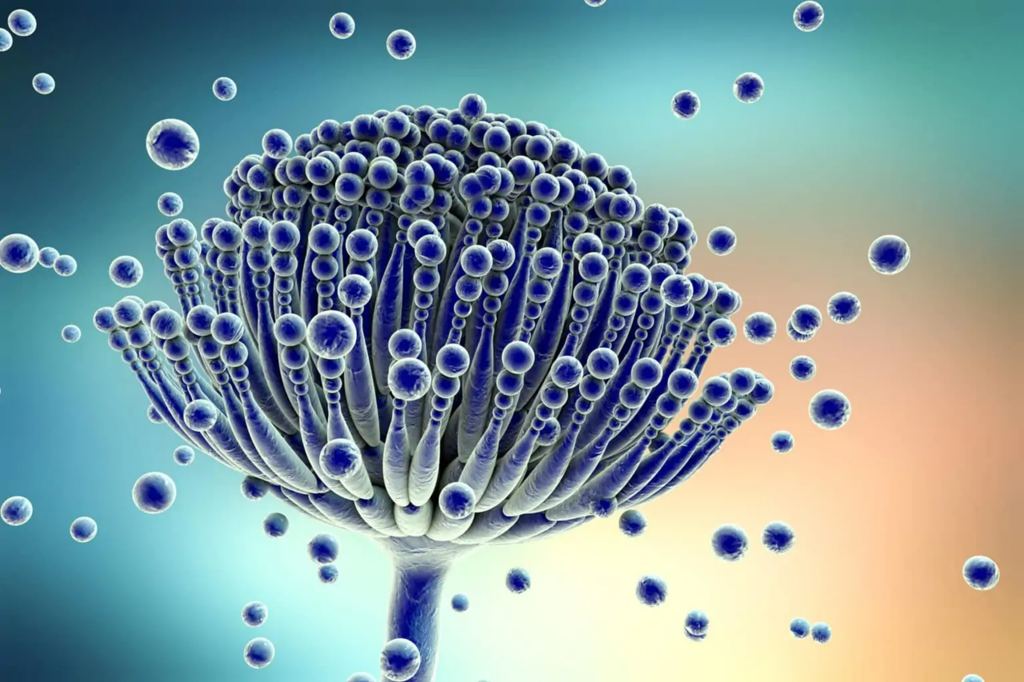

Mycotoxins appear in the food chain resulting from fungal infections of crops before and after harvest. Mycotoxins-producing fungi grow on a variety of crops and numerous food products including cereals, nuts, spices, coffee, cocoa, beans, and lentils. They thrive in warm and humid conditions and can penetrate deep into the seeds. When crops are not dried properly and stored safely, the chances of contamination with fungi and their Mycotoxin metabolites are very high. Exposure to Mycotoxins can occur directly by eating infected food or indirectly through animals that have been fed contaminated feed. Thereby, mycotoxins can pose serious challenges to human and animal health all while presenting significant economic challenges as well for both farmers and the industry.

Using ozonation to ensure high-quality food and feed

To overcome the problems posed by crops contaminated with Mycotoxins, TOXI-SCRUB ApS has developed a processing line that overcomes this exact challenge as well as removing other biological organisms such as bacteria, mites, and insects from crops. The TOXI-SCRUB® technology uses an ozonation process to reduce Mycotoxin levels safely below the accepted threshold for humans and animals. Ozonation is the process in which a commodity is exposed to Ozone, during which Mycotoxin molecules are oxidised. This method is efficient because it oxidises the double bonds in the “energy-rich” molecules and, in this way, breaks the molecular structure and creates new non-toxic molecules. This technique can be used pre-storage to ensure safe long-term storage or pre-processing to ensure high-quality feed or food. The TOXI-SCRUB® solution is a green technology that is friendly to humans, animals, and the environment, and it does not leave any residuals in the detoxified crop. Ozonation is generally recognized as safe (GRAS) by the United States Food and Drug Administration and it can even be used in the supply chain of organic food.

Efficient eradication of harmful Mycotoxins

TOXI-SCRUB ApS has developed an application range for TOXI-SCRUB® covering general grain storage, flour mills, maize flour mills, feed mills, and nut processing. The processing line can be manufactured to process from 2 to 40 tonnes of crops per hour, turning contaminated crops into detoxified crops. With a treatment cost of only USD 3.0-5.0 per tonne, the feasibility is excellent. Also, more than 100 scientific articles have confirmed the efficiency of Ozone in eradicating most of the harmful Mycotoxins significant to the food supply chain for food and feed processing.

You can also read the original article on FoodNation.