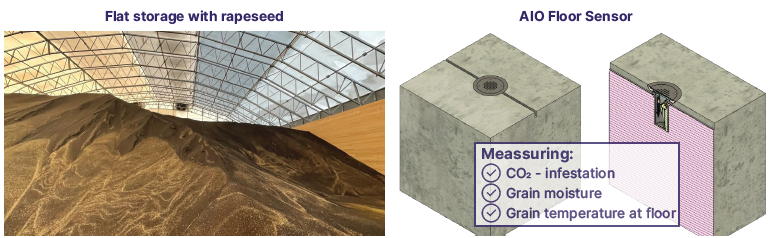

All-In-One Floor Sensor (AIO)

Grain monitoring in flat storage facilities has challenges:

- Ventilation: Stored grain is difficult to ventilate properly even if aeration channels are in place

- Moisture: The corners of the flat stores are often accumulating moisture and acts as an “initiator” of infestation

- Front loader access: Sensor cables hanging from the roof are inconvenient for the front loaders moving the grain in/out. Damages easily occur.

- Risk warning: Temperature monitoring is a poor solution because it detects hot spots very late and by the time you receive an alarm, there is already significant infestation/spoilage in the grain.

- Uniform readings: Hot spots often emerge in the corners or along the walls and sensor lances are not efficient enough even when placed closer to the walls.

- Manual labour: Substantial manual labour required when using sensor lances for monitoring

iGRAIN has the solution:

CO2 infestation monitoring is strongly recommended, as temperature sensors are slow to warn about infestation. The fastest and most reliable method is to monitor the CO2 concentration and the grain moisture. The iGRAIN solution is a combination of:

- Hidden sensors in the floor so they don’t obstruct front loaders

- Monitoring the CO2 for early infestation control. *

- Monitoring both humidity and temperature for grain moisture control

* Since CO2 is a gas and all gases spreads evenly in all directions, you only need few sensors

Advantages:

- You receive reports with the TRUE grain condition

- You can follow the development in real time in your iGRAIN smart app

- You receive an AI based calculation of longest possible SAFE storage time

- No manual labour required

- You can freely move the grain around without the front loaders getting obstructed by cables/spears and causing damage to the sensors.

Contact / request offer:

Please contact our sales and application team at info@i-grain.net for further information and a quote to suit your specific needs.

Download PDF