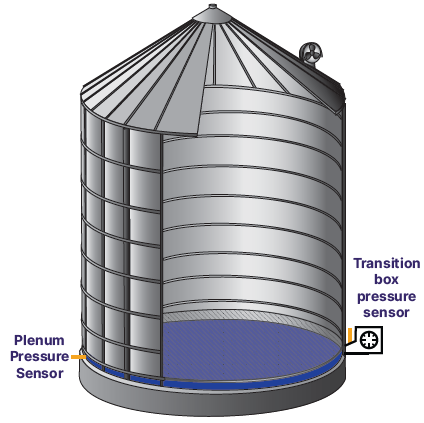

Plenum Pressure Sensor - for aeration monitoring and air flow calculation

The iGRAIN Plenum Pressure Sensor confirms that the aeration control takes place at the right time. Situated in the silo plenum space or in the transition box from the aeration fan, the pressure sensor confirms that the aeration fan is running; this is necessary because when the iGRAIN dashboard software determines that the fans should run, then an alarm will be triggered if it does not happen. And vise versa, if the fan is running when the software has calculated it is not advantageous, then another alarm will be triggered.

The iGRAIN Plenum Pressure Sensor confirms that the aeration control takes place at the right time. Situated in the silo plenum space or in the transition box from the aeration fan, the pressure sensor confirms that the aeration fan is running; this is necessary because when the iGRAIN dashboard software determines that the fans should run, then an alarm will be triggered if it does not happen. And vise versa, if the fan is running when the software has calculated it is not advantageous, then another alarm will be triggered.

The airflow through the grain during aeration is also important. The aeration control depends on the silo size, the commodity, and the climatic zone etc. and must be matched with the airflow. When the pressure-flow diagram is provided to iGRAIN the software is set up to show the real airflow through the silo; shown as m3/ton/hours or CFM per ton. This enables a better aeration control.

The advanced automatic iGRAIN aeration control system makes use of the flow rate calculating when to start/stop the fans. This is important to reach the moisture and temperature target for the grain condition in the most efficient way.

The pressure sensors are connected to the iGRAIN AIO-Hub. A CAT6 cable can be used for both power and the MODBUS data communication. The AIO-Hub can be connected to other sensors in the AIO family since they share the 24 VDC and the universal MODBUS communication protocol.

Download PDF